Preamble

This is the thirteenth post in the "Art Resource" series, specifically aimed to construct an appropriate knowledge base in order to develop an artistic voice in ArtCloth.

Other posts in this series are:

Glossary of Cultural and Architectural Terms

Units Used in Dyeing and Printing of Fabrics

Occupational, Health & Safety

A Brief History of Color

The Nature of Color

Psychology of Color

Color Schemes

The Naming of Colors

The Munsell Color Classification System

Methuen Color Index and Classification System

The CIE System

Pantone - A Modern Color Classification System

Optical Properties of Fiber Materials

General Properties of Fiber Polymers and Fibers - Part I

General Properties of Fiber Polymers and Fibers - Part II

General Properties of Fiber Polymers and Fibers - Part III

General Properties of Fiber Polymers and Fibers - Part IV

General Properties of Fiber Polymers and Fibers - Part V

Protein Fibers - Wool

Protein Fibers - Speciality Hair Fibers

Protein Fibers - Silk

Protein Fibers - Wool versus Silk

Timelines of Fabrics, Dyes and Other Stuff

Cellulosic Fibers (Natural) - Cotton

Cellulosic Fibers (Natural) - Linen

Other Natural Cellulosic Fibers

General Overview of Man-Made Fibers

Man-Made Cellulosic Fibers - Viscose

Man-Made Cellulosic Fibers - Esters

Man-Made Synthetic Fibers - Nylon

Man-Made Synthetic Fibers - Polyester

Man-Made Synthetic Fibers - Acrylic and Modacrylic

Man-Made Synthetic Fibers - Olefins

Man-Made Synthetic Fibers - Elastomers

Man-Made Synthetic Fibers - Mineral Fibers

Man Made Fibers - Other Textile Fibers

Fiber Blends

From Fiber to Yarn: Overview - Part I

From Fiber to Yarn: Overview - Part II

Melt-Spun Fibers

Characteristics of Filament Yarn

Yarn Classification

Direct Spun Yarns

Textured Filament Yarns

Fabric Construction - Felt

Fabric Construction - Nonwoven fabrics

A Fashion Data Base

Fabric Construction - Leather

Fabric Construction - Films

Glossary of Colors, Dyes, Inks, Pigments and Resins

Fabric Construction – Foams and Poromeric Material

Knitting

Hosiery

Glossary of Fabrics, Fibers, Finishes, Garments and Yarns

Weaving and the Loom

Similarities and Differences in Woven Fabrics

The Three Basic Weaves - Plain Weave (Part I)

The Three Basic Weaves - Plain Weave (Part II)

The Three Basic Weaves - Twill Weave

The Three Basic Weaves - Satin Weave

Figured Weaves - Leno Weave

Figured Weaves – Piqué Weave

Figured Fabrics

Glossary of Art, Artists, Art Motifs and Art Movements

Crêpe Fabrics

Crêpe Effect Fabrics

Pile Fabrics - General

Woven Pile Fabrics

Chenille Yarn and Tufted Pile Fabrics

Knit-Pile Fabrics

Flocked Pile Fabrics and Other Pile Construction Processes

Glossary of Paper, Photography, Printing, Prints and Publication Terms

Napped Fabrics – Part I

Napped Fabrics – Part II

Double Cloth

Multicomponent Fabrics

Knit-Sew or Stitch Through Fabrics

Finishes - Overview

Finishes - Initial Fabric Cleaning

Mechanical Finishes - Part I

Mechanical Finishes - Part II

Additive Finishes

Chemical Finishes - Bleaching

Glossary of Scientific Terms

Chemical Finishes - Acid Finishes

Finishes: Mercerization

Finishes: Waterproof and Water-Repellent Fabrics

Finishes: Flame-Proofed Fabrics

Finishes to Prevent Attack by Insects and Micro-Organisms

Other Finishes

Shrinkage - Part I

Shrinkage - Part II

Progressive Shrinkage and Methods of Control

Durable Press and Wash-and-Wear Finishes - Part I

Durable Press and Wash-and-Wear Finishes - Part II

Durable Press and Wash-and-Wear Finishes - Part III

Durable Press and Wash-and-Wear Finishes - Part IV

Durable Press and Wash-and-Wear Finishes - Part V

The General Theory of Dyeing – Part I

The General Theory Of Dyeing - Part II

Natural Dyes

Natural Dyes - Indigo

Mordant Dyes

Premetallized Dyes

Azoic Dyes

Basic Dyes

Acid Dyes

Disperse Dyes

Direct Dyes

Reactive Dyes

Sulfur Dyes

Blends – Fibers and Direct Dyeing

The General Theory of Printing

There are currently eight data bases on this blogspot, namely, the Glossary of Cultural and Architectural Terms, Timelines of Fabrics, Dyes and Other Stuff, A Fashion Data Base, the Glossary of Colors, Dyes, Inks, Pigments and Resins, the Glossary of Fabrics, Fibers, Finishes, Garments and Yarns, Glossary of Art, Artists, Art Motifs and Art Movements, Glossary of Paper, Photography, Printing, Prints and Publication Terms and the Glossary of Scientific Terms, which has been updated to Version 3.5. All data bases will be updated from time-to-time in the future.

If you find any post on this blog site useful, you can save it or copy and paste it into your own "Word" document etc. for your future reference. For example, Safari allows you to save a post (e.g. click on "File", click on "Print" and release, click on "PDF" and then click on "Save As" and release - and a PDF should appear where you have stored it). Safari also allows you to mail a post to a friend (click on "File", and then point cursor to "Mail Contents On This Page" and release). Either way, this or other posts on this site may be a useful Art Resource for you.

The Art Resource series will be the first post in each calendar month. Remember - these Art Resource posts span information that will be useful for a home hobbyist to that required by a final year University Fine-Art student and so undoubtedly, some parts of any Art Resource post may appear far too technical for your needs (skip over those mind boggling parts) and in other parts, it may be too simplistic with respect to your level of knowledge (ditto the skip). The trade-off between these two extremes will mean that Art Resource posts will hopefully be useful in parts to most, but unfortunately may not be satisfying to all!

Introduction

A fabric can reflect, absorb or transmit visible light falling on it. The hue of a fabric depends on the extent to which the light is reflected, absorbed or transmitted. Thus, the optical properties of fabrics need to be taken into consideration when dyeing, printing or color matching fabrics. Note: From here on I shall use the term "fabric" to mean materials that are woven and unwoven, whereas the the term "textiles" shall only by used for woven materials. The term "cloth" will also be used as woven or unwoven materials. Textiles are therefore a sub-category of fabrics and cloths.

Generally, one or more of the following affects optical properties of fabrics:

(i) Type of fiber used.

(ii) Type of yarn.

(iii) Fabric construction.

(iv) Surface properties of the fabric.

(v) Overall optical properties of the fabric.

(vi) The subjective nature of color vision.

The figure below demonstrates the complexity with respect to the interaction of a fabric with incident white light[1].

Figurative depiction of an incident ray of white light interacting with a fabric[1].

The figure above demonstrates that white light is reflected from the surface, whereas colored light is reflected from the amorphous region of the fabric, an area in which the dye molecules are bonded (i.e. fixed) to the fiber molecules of the fabric. If the fabric is translucent or thin enough, the colored transmitted light can escape, giving it a “see through” or transparent effect.

Metamerism

When a dyed or printed fabric is examined under different lighting conditions, a marked change in its color may be observed. This phenomenon is known as "metamerism". Two fabric materials may appear to possess the same color when viewed under one type of illumination, but will appear to have a different color when view under another type of illumination. If this occurs the fabrics are said to be a metameric match.

The problem of metameric matches may arise when two fibers of different chemical composition, such as cotton and polyester for instance, have to be dyed the same color. Due to the different chemical composition of the fibers, they invariably cannot be dyed successfully with the same dye. Rather a different dye is required for each fiber to achieve the same color. Then in all likelihood, the similarly appearing colors achieved with the two different dyes will have different spectral properties (e.g. their spectral reflectance curves will not be alike). Thus the fibers will apear to possess different colors under one type of illumination, but have similar colors under another.

To avoid metamerism, the reflectance curves of the two or more colored fabrics must coincide at all wavelengths, which ensures that the same color is obtained under any type of illumination.

Should metamerism occur, it will undoubtedly cause problems for the fabric dyer. For example, a metameric fabric material that appears green in sunlight may appear as a khaki color under room light conditions etc.

Optical Properties of Fibers

Lustrous and Translucent Fibers

In general the properties of “luster” and “translucency” of fibers are interdependent and so occur together. Fibers in this category include the bright lustered man-made fibers, flaxes and silks. The lustrous property is due to a high proportion of white light that is reflected very evenly by the smooth regular surface of the fiber. However, the irregular surface of viscose rayon or that of the acetate fibers appear to have little effect on the extent of luster.

Flax fiber is soft, lustrous and flexible.

Dyed viscose rayon filament.

The more white light that is reflected, the greater the appearance of luster and so the lighter the appearance of the hue of the fiber. The reflected light stimulates the rods of the retina in our eyes. These rods differentiate shades of grey, lightness or darkness. This causes our brain to perceive more white light and so fools us into believing the hue is lighter than what it actually is. In addition, the fibers’ translucency allows partial transmission of light and so enables our eyes to “see through” the fiber. This reduces the amount of hue actually seen and so adds to the sensation of seeing a lighter hue.

Basic cross-section of the eye.

The background against which the fiber is examined, also affects the hue of the colored fabric material. The fiber’s translucent characteristic together with the color of the background, may affect the chroma and/or the value of the color that is perceived by the brain.

Translucent silk fibers.

Delustered Fibers

Man-made fibers are delustered using titantium oxide (TiO2) a white, finely powdered pigment (which is also used in sun screens). These fine particles of TiO2 scatter the reflected white light from the delustered fibers and so subdues the lustered appearance of the fabric. The colors of dyed or printed delustered fibers now appear brighter than the appearance on luster fabrics, since in the case of the latter, the reflected white light tends to dilute or lighten the color reflected by the dyed molecules.

Marie-Therese Wisniowski - Sequestration of CO2 (Detailed View) - a MultiSperse Dye Sublimation (MSDS) technique on a delustered satin.

Opaque and Dull Fibers

Opaque and dull fibers generally are cotton and wool fibers, both of which reflect very little, if any, white light. They tend to absorb most of the incident white light, giving a greyish-white appearance. Hence the lack of lightness and brightness of dyed and printed cotton and wool textile materials, compared with their man-made equivalents is due to this light absorption.

Opaque satin stripe.

Most cotton fabrics are bleached before color is applied, which makes them appear lighter and brighter than their unbleached variants. On the other hand, wool is not generally bleached as often and so tends to appear dull, which is also progressively promoted due to atmospheric oxidation reactions.

Effect of Fiber Fineness

Dyeing equal masses of fine and course fibers, with the same quantity of dye, results in the coarse fibers appearing to be darker than the fine fibers. This is because there will be more fine fibers compared with coarse fibers per unit mass. Hence, for coarse fibers more dye can be taken up per unit mass of fiber than with respect to fine fibers (under identical dyeing conditions). This must be taken into account when trying to color match fibers of different diameters.

Close-up photograph of coarse fibers.

It is very important to note that the above is only applicable to the dyeing process AND NOT to printing, since in the latter process the dye/pigment is applied uniformly per unit surface area of the fabric.

Mercerized Cotton

The process of mercerizing cotton improves the dye uptake. This enables deeper colors (i.e. colors with more chroma) to be obtained with mercerized cotton.

Dyed mercerized cotton broadcloth.

The colors of cotton, which are stretched or tension mercerized appear lighter and brighter than colors of unmercertized cottons. This is due to the mercerizing process enabling more white light to be reflected from the surface of the fabric, thereby increasing the value of the color.

Optical Properties of Yarns

Filament versus Staple Spun Yarns

Filament yarns are much smoother than staple spun yarns. They reflect more white light, which makes them more lusterous. If this luster is significant, the yarn can be perceived as having a color of higher value and less chroma than is actually present. Staple spun yarns have little if any luster and so appear darker (i.e. have a lower value) than comparably colored filament yarns. This is due to the staple spun yarns having a more irregular surface than filament yarns and so are unable to reflect the incident white light to the same extent as the smooth filament yarns.

Metallic staple fiber.

High Twist (Hard Spun) versus Low Twist (Soft Spun) Yarns

High twist yarns have a smooth, more regular surface compared to soft spun yarns. Soft spun yarns have a more hairy, less regular surface. Hence, high twist yarns reflect more incident white light compared with low twist yarns, giving the former more luster. Thus, hard spun yarns will have a more lusterous, lighter, brighter appearance compared with an equivalently colored soft spun yarn.

Fluffy yarn.

Thick Yarns versus Thin Yarns

Thick yarns tend to appear duller and darker compared with equivalently colored thin yarns. The structure of the thicker yarns results in more light being absorbed, which results in the color being darker compared to thinner yarns. Hence, thicker yarns have a lower value and chroma compared with equivalently colored thin yarns.

Thick yarns.

Thin yarns.

Textured Yarns

The irregular surface of textured yarns absorbs much light and scatters most of the white reflected light. This produces color lower in value than an equivalently colored yarn, which is not textured.

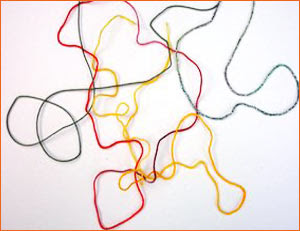

Textured yarns.

Optical Properties of Fabrics

There are many factors, which influence both the structure and surface characteristics of knitted, woven and the new forms of fabrics. The explanations given above for fibers and yarns and those that follow for fabrics should provide useful guidelines for the optical properties of fabrics.

Smooth and Irregular Fabric Surface Structures

Smooth fabrics possess smooth and regular surface structures and so even if they are not lusterous, they nevertheless reflect some of the white incident light and so lighten the color of dyed or printed textile material.

Silk fabric texture smooth satin cloth surface.

The color of smooth fabrics will have a lighter value or color compared with fabrics with a raised, brushed, napped or other irregular surface. Fabrics with an irregular surface absorb more of the white incident light than those with smoother surfaces, and so the former fabrics appear duller than the latter fabrics. The irregular surface fabrics have a lower value and chroma than the equivalent but smooth surfaced fabrics.

Cotton yarn dyed napped Jacqard fabric.

The optical properties of lusterous fabrics are the same as those given above for lusterous, translucent fibers and filament yarns. The color of a particular form of fabric will be affected by the surface of the fabric as well as by the optical properties of fibers and yarns from which they are produced.

Opaque and Translucent Fabrics

Opaque fabrics have a darker, duller color (i.e. less chroma and value) since these fabrics absorb most of the incident white light. Translucent fabrics have a lighter color than an equivalent opaque fabric. The color of a garment made from a translucent fabric will be influenced by the color and optical properties of the fabric as well as by the color of the skin against which the fabric is worn.

The Subjective Nature of Color Vision

Scientific instruments such as spectrophotometers (developed to measure color) have shown that each color is composed of specific wavelengths. The eye, however, is unable to view color consistently. This inability means that the color vision of human beings is subjective and so differences can be attributable to all or some of the following factors.

Tiredness of Eyes

This occurs when eyes are made to concentrate too long on one or a combination of colored objects. One of the following may result.

Positive After-Image

Prolonged exposure to a colored object may result in colors being seen for a few seconds after the object has been removed from view. This effect is called positive after-image. The effect is due to excessive stimulation of the photo-chemical substance within the retina. The excessive stimulation temporarily prevents the photo-chemical substance in the retina from regeneration, making the retina momentarily insensitive to light.

Successive Contrast

This occurs when, having concentrated upon a colored object, the eyes are turned away and see the complementary color(s) of the color(s) just viewed. Successive contrast is the most commonest type of after-vision. There is no simple explanation for this phenomenon.

Simultaneous Contrast

Sometimes an object being observed appears to be surrounded by a halo, or tinged with its complementary colors. This effect is called simultaneous contrast.

It is important to rest one's eyes regularly when making color comparisons to prevent any of the effects described above.

Emotional State of the Observer

The emotional state or past experiences involving colors can cause an observer to perceive colors differently.

Type of Illumination

Different sources of illumination will greatly influence the colors perceived by people.

Poor Illumination

Poor illumination provides inadequate light energy to stimulate the cones and so correctly perceive the actual color of the material being observed. With poor illumination, only the rods of the retina may be stimulated and colors observed will be restricted to shades of grey, black and faint green.

Direct Sunlight

Direct sunlight is characterized by a slightly yellow white light. That is because the colors yellow, orange and red represent over 40% of the sun's color spectrum - yielding the white color of sunlight a very slight yellow-red hue. Hence this source of light tends to impart a slight yellow tinge to all colors. The observer tends to ignore the slight yellow tinge of direct sunlight (which is picked up by a spectrophotometer) and so white paper appears white to the eye despite the yellow component of direct sunlight.

Indirect Sunlight

This is also referred to as south-light or north-light and is a blue-white light. South-light (i.e. a light reflected from the southern sky during daylight hours) contains an excess of blue light energy, because the molecules of the air scatter blue light waves more than the waves of the other colors.

This light tends to impart a slight blue tinge to all hues (as detected by a spectrophotometer). The observer tends to ignore the slight blueing effect of indirect sunlight.

Note: As a general rule blue-white is considered whiter white than yellow-white. Yellow-white materials give the impression of being somewhat soiled. The practice of "blueing" white laundry is still quite common, although this is more frequently and effectively carried out using optical brighteners, which are found in most domestic laundry detergents.

Incandescent Light

Incandescent light lacks the blue component of light. For example, most electric light bulbs emit incandescent light. This contains an excess of yellow and red light energy. Hence incandescent light is yellowish, although the eyes still perceive it as white light, until of course it is compared with fluorescent light.

Incandescent light therefore imparts a distinctly yellow-red appearance and has a similar effect on colors to direct sunlight.

Fluorescent Light

This light lacks yellow light waves. It contains an excess of blue and green light energy and a deficiency of red. Fluorescent light has a distinct blue color, although the eyes and brain will perceive it as a sterilized white light. The blueness of this light brightens any colors exposed to it.

Intensity of Illumination

The retina of the eyes needs time to adapt to varying levels of illumination. It takes time for the eye to adjust when one goes from a brightly lit area to one with little light and vice vera.

Contrast

Perception of colors can be influenced by the background against which the colored object is viewed. A yellow textile material when viewed against a grey background will result in the yellow hue having more value and chroma; that is, it will appear brighter than if it were viewed against a yellow background.

Age of the Observer

The natural ageing process of the hunman body will reduce one's ability to respond to various stimuli. Ageing yellows the lens of the eye and increases the yellow pigment in the central region of the retina. This results in older people seeing more yellow in colors, a fact which is not often accepted by older people.

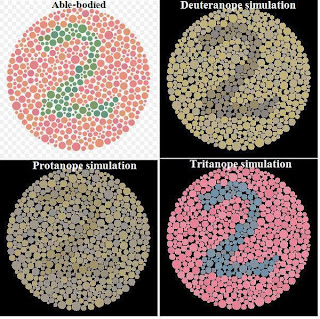

Defective Color Vision

Approximately 8% of the male population and about 2% of the female population have defective color vision in one or more forms. Defective color vision can be described as the inability to see primary colors correctly and, in some instances, the inability to see color at all. The latter form of defective color vision results in the individuals being able to only see white, black and a range of greys. A person with this defect would sit in front of a color television set and would see a program in black and white only. Defective color vision is a sex-linked hereditary characteristic.

What number can you see in each of these discs?

Reference:

[1] E.P.G. Gohl and L.D. Vilensky, Textile Science, Longman Cheshire, Melbourne (1989).

This is the thirteenth post in the "Art Resource" series, specifically aimed to construct an appropriate knowledge base in order to develop an artistic voice in ArtCloth.

Other posts in this series are:

Glossary of Cultural and Architectural Terms

Units Used in Dyeing and Printing of Fabrics

Occupational, Health & Safety

A Brief History of Color

The Nature of Color

Psychology of Color

Color Schemes

The Naming of Colors

The Munsell Color Classification System

Methuen Color Index and Classification System

The CIE System

Pantone - A Modern Color Classification System

Optical Properties of Fiber Materials

General Properties of Fiber Polymers and Fibers - Part I

General Properties of Fiber Polymers and Fibers - Part II

General Properties of Fiber Polymers and Fibers - Part III

General Properties of Fiber Polymers and Fibers - Part IV

General Properties of Fiber Polymers and Fibers - Part V

Protein Fibers - Wool

Protein Fibers - Speciality Hair Fibers

Protein Fibers - Silk

Protein Fibers - Wool versus Silk

Timelines of Fabrics, Dyes and Other Stuff

Cellulosic Fibers (Natural) - Cotton

Cellulosic Fibers (Natural) - Linen

Other Natural Cellulosic Fibers

General Overview of Man-Made Fibers

Man-Made Cellulosic Fibers - Viscose

Man-Made Cellulosic Fibers - Esters

Man-Made Synthetic Fibers - Nylon

Man-Made Synthetic Fibers - Polyester

Man-Made Synthetic Fibers - Acrylic and Modacrylic

Man-Made Synthetic Fibers - Olefins

Man-Made Synthetic Fibers - Elastomers

Man-Made Synthetic Fibers - Mineral Fibers

Man Made Fibers - Other Textile Fibers

Fiber Blends

From Fiber to Yarn: Overview - Part I

From Fiber to Yarn: Overview - Part II

Melt-Spun Fibers

Characteristics of Filament Yarn

Yarn Classification

Direct Spun Yarns

Textured Filament Yarns

Fabric Construction - Felt

Fabric Construction - Nonwoven fabrics

A Fashion Data Base

Fabric Construction - Leather

Fabric Construction - Films

Glossary of Colors, Dyes, Inks, Pigments and Resins

Fabric Construction – Foams and Poromeric Material

Knitting

Hosiery

Glossary of Fabrics, Fibers, Finishes, Garments and Yarns

Weaving and the Loom

Similarities and Differences in Woven Fabrics

The Three Basic Weaves - Plain Weave (Part I)

The Three Basic Weaves - Plain Weave (Part II)

The Three Basic Weaves - Twill Weave

The Three Basic Weaves - Satin Weave

Figured Weaves - Leno Weave

Figured Weaves – Piqué Weave

Figured Fabrics

Glossary of Art, Artists, Art Motifs and Art Movements

Crêpe Fabrics

Crêpe Effect Fabrics

Pile Fabrics - General

Woven Pile Fabrics

Chenille Yarn and Tufted Pile Fabrics

Knit-Pile Fabrics

Flocked Pile Fabrics and Other Pile Construction Processes

Glossary of Paper, Photography, Printing, Prints and Publication Terms

Napped Fabrics – Part I

Napped Fabrics – Part II

Double Cloth

Multicomponent Fabrics

Knit-Sew or Stitch Through Fabrics

Finishes - Overview

Finishes - Initial Fabric Cleaning

Mechanical Finishes - Part I

Mechanical Finishes - Part II

Additive Finishes

Chemical Finishes - Bleaching

Glossary of Scientific Terms

Chemical Finishes - Acid Finishes

Finishes: Mercerization

Finishes: Waterproof and Water-Repellent Fabrics

Finishes: Flame-Proofed Fabrics

Finishes to Prevent Attack by Insects and Micro-Organisms

Other Finishes

Shrinkage - Part I

Shrinkage - Part II

Progressive Shrinkage and Methods of Control

Durable Press and Wash-and-Wear Finishes - Part I

Durable Press and Wash-and-Wear Finishes - Part II

Durable Press and Wash-and-Wear Finishes - Part III

Durable Press and Wash-and-Wear Finishes - Part IV

Durable Press and Wash-and-Wear Finishes - Part V

The General Theory of Dyeing – Part I

The General Theory Of Dyeing - Part II

Natural Dyes

Natural Dyes - Indigo

Mordant Dyes

Premetallized Dyes

Azoic Dyes

Basic Dyes

Acid Dyes

Disperse Dyes

Direct Dyes

Reactive Dyes

Sulfur Dyes

Blends – Fibers and Direct Dyeing

The General Theory of Printing

There are currently eight data bases on this blogspot, namely, the Glossary of Cultural and Architectural Terms, Timelines of Fabrics, Dyes and Other Stuff, A Fashion Data Base, the Glossary of Colors, Dyes, Inks, Pigments and Resins, the Glossary of Fabrics, Fibers, Finishes, Garments and Yarns, Glossary of Art, Artists, Art Motifs and Art Movements, Glossary of Paper, Photography, Printing, Prints and Publication Terms and the Glossary of Scientific Terms, which has been updated to Version 3.5. All data bases will be updated from time-to-time in the future.

If you find any post on this blog site useful, you can save it or copy and paste it into your own "Word" document etc. for your future reference. For example, Safari allows you to save a post (e.g. click on "File", click on "Print" and release, click on "PDF" and then click on "Save As" and release - and a PDF should appear where you have stored it). Safari also allows you to mail a post to a friend (click on "File", and then point cursor to "Mail Contents On This Page" and release). Either way, this or other posts on this site may be a useful Art Resource for you.

The Art Resource series will be the first post in each calendar month. Remember - these Art Resource posts span information that will be useful for a home hobbyist to that required by a final year University Fine-Art student and so undoubtedly, some parts of any Art Resource post may appear far too technical for your needs (skip over those mind boggling parts) and in other parts, it may be too simplistic with respect to your level of knowledge (ditto the skip). The trade-off between these two extremes will mean that Art Resource posts will hopefully be useful in parts to most, but unfortunately may not be satisfying to all!

Introduction

A fabric can reflect, absorb or transmit visible light falling on it. The hue of a fabric depends on the extent to which the light is reflected, absorbed or transmitted. Thus, the optical properties of fabrics need to be taken into consideration when dyeing, printing or color matching fabrics. Note: From here on I shall use the term "fabric" to mean materials that are woven and unwoven, whereas the the term "textiles" shall only by used for woven materials. The term "cloth" will also be used as woven or unwoven materials. Textiles are therefore a sub-category of fabrics and cloths.

Generally, one or more of the following affects optical properties of fabrics:

(i) Type of fiber used.

(ii) Type of yarn.

(iii) Fabric construction.

(iv) Surface properties of the fabric.

(v) Overall optical properties of the fabric.

(vi) The subjective nature of color vision.

The figure below demonstrates the complexity with respect to the interaction of a fabric with incident white light[1].

Figurative depiction of an incident ray of white light interacting with a fabric[1].

The figure above demonstrates that white light is reflected from the surface, whereas colored light is reflected from the amorphous region of the fabric, an area in which the dye molecules are bonded (i.e. fixed) to the fiber molecules of the fabric. If the fabric is translucent or thin enough, the colored transmitted light can escape, giving it a “see through” or transparent effect.

Metamerism

When a dyed or printed fabric is examined under different lighting conditions, a marked change in its color may be observed. This phenomenon is known as "metamerism". Two fabric materials may appear to possess the same color when viewed under one type of illumination, but will appear to have a different color when view under another type of illumination. If this occurs the fabrics are said to be a metameric match.

The problem of metameric matches may arise when two fibers of different chemical composition, such as cotton and polyester for instance, have to be dyed the same color. Due to the different chemical composition of the fibers, they invariably cannot be dyed successfully with the same dye. Rather a different dye is required for each fiber to achieve the same color. Then in all likelihood, the similarly appearing colors achieved with the two different dyes will have different spectral properties (e.g. their spectral reflectance curves will not be alike). Thus the fibers will apear to possess different colors under one type of illumination, but have similar colors under another.

To avoid metamerism, the reflectance curves of the two or more colored fabrics must coincide at all wavelengths, which ensures that the same color is obtained under any type of illumination.

Should metamerism occur, it will undoubtedly cause problems for the fabric dyer. For example, a metameric fabric material that appears green in sunlight may appear as a khaki color under room light conditions etc.

Optical Properties of Fibers

Lustrous and Translucent Fibers

In general the properties of “luster” and “translucency” of fibers are interdependent and so occur together. Fibers in this category include the bright lustered man-made fibers, flaxes and silks. The lustrous property is due to a high proportion of white light that is reflected very evenly by the smooth regular surface of the fiber. However, the irregular surface of viscose rayon or that of the acetate fibers appear to have little effect on the extent of luster.

Flax fiber is soft, lustrous and flexible.

Dyed viscose rayon filament.

The more white light that is reflected, the greater the appearance of luster and so the lighter the appearance of the hue of the fiber. The reflected light stimulates the rods of the retina in our eyes. These rods differentiate shades of grey, lightness or darkness. This causes our brain to perceive more white light and so fools us into believing the hue is lighter than what it actually is. In addition, the fibers’ translucency allows partial transmission of light and so enables our eyes to “see through” the fiber. This reduces the amount of hue actually seen and so adds to the sensation of seeing a lighter hue.

Basic cross-section of the eye.

The background against which the fiber is examined, also affects the hue of the colored fabric material. The fiber’s translucent characteristic together with the color of the background, may affect the chroma and/or the value of the color that is perceived by the brain.

Translucent silk fibers.

Delustered Fibers

Man-made fibers are delustered using titantium oxide (TiO2) a white, finely powdered pigment (which is also used in sun screens). These fine particles of TiO2 scatter the reflected white light from the delustered fibers and so subdues the lustered appearance of the fabric. The colors of dyed or printed delustered fibers now appear brighter than the appearance on luster fabrics, since in the case of the latter, the reflected white light tends to dilute or lighten the color reflected by the dyed molecules.

Marie-Therese Wisniowski - Sequestration of CO2 (Detailed View) - a MultiSperse Dye Sublimation (MSDS) technique on a delustered satin.

Opaque and Dull Fibers

Opaque and dull fibers generally are cotton and wool fibers, both of which reflect very little, if any, white light. They tend to absorb most of the incident white light, giving a greyish-white appearance. Hence the lack of lightness and brightness of dyed and printed cotton and wool textile materials, compared with their man-made equivalents is due to this light absorption.

Opaque satin stripe.

Most cotton fabrics are bleached before color is applied, which makes them appear lighter and brighter than their unbleached variants. On the other hand, wool is not generally bleached as often and so tends to appear dull, which is also progressively promoted due to atmospheric oxidation reactions.

Effect of Fiber Fineness

Dyeing equal masses of fine and course fibers, with the same quantity of dye, results in the coarse fibers appearing to be darker than the fine fibers. This is because there will be more fine fibers compared with coarse fibers per unit mass. Hence, for coarse fibers more dye can be taken up per unit mass of fiber than with respect to fine fibers (under identical dyeing conditions). This must be taken into account when trying to color match fibers of different diameters.

Close-up photograph of coarse fibers.

It is very important to note that the above is only applicable to the dyeing process AND NOT to printing, since in the latter process the dye/pigment is applied uniformly per unit surface area of the fabric.

Mercerized Cotton

The process of mercerizing cotton improves the dye uptake. This enables deeper colors (i.e. colors with more chroma) to be obtained with mercerized cotton.

Dyed mercerized cotton broadcloth.

The colors of cotton, which are stretched or tension mercerized appear lighter and brighter than colors of unmercertized cottons. This is due to the mercerizing process enabling more white light to be reflected from the surface of the fabric, thereby increasing the value of the color.

Optical Properties of Yarns

Filament versus Staple Spun Yarns

Filament yarns are much smoother than staple spun yarns. They reflect more white light, which makes them more lusterous. If this luster is significant, the yarn can be perceived as having a color of higher value and less chroma than is actually present. Staple spun yarns have little if any luster and so appear darker (i.e. have a lower value) than comparably colored filament yarns. This is due to the staple spun yarns having a more irregular surface than filament yarns and so are unable to reflect the incident white light to the same extent as the smooth filament yarns.

Metallic staple fiber.

High Twist (Hard Spun) versus Low Twist (Soft Spun) Yarns

High twist yarns have a smooth, more regular surface compared to soft spun yarns. Soft spun yarns have a more hairy, less regular surface. Hence, high twist yarns reflect more incident white light compared with low twist yarns, giving the former more luster. Thus, hard spun yarns will have a more lusterous, lighter, brighter appearance compared with an equivalently colored soft spun yarn.

Fluffy yarn.

Thick Yarns versus Thin Yarns

Thick yarns tend to appear duller and darker compared with equivalently colored thin yarns. The structure of the thicker yarns results in more light being absorbed, which results in the color being darker compared to thinner yarns. Hence, thicker yarns have a lower value and chroma compared with equivalently colored thin yarns.

Thick yarns.

Thin yarns.

Textured Yarns

The irregular surface of textured yarns absorbs much light and scatters most of the white reflected light. This produces color lower in value than an equivalently colored yarn, which is not textured.

Textured yarns.

Optical Properties of Fabrics

There are many factors, which influence both the structure and surface characteristics of knitted, woven and the new forms of fabrics. The explanations given above for fibers and yarns and those that follow for fabrics should provide useful guidelines for the optical properties of fabrics.

Smooth and Irregular Fabric Surface Structures

Smooth fabrics possess smooth and regular surface structures and so even if they are not lusterous, they nevertheless reflect some of the white incident light and so lighten the color of dyed or printed textile material.

Silk fabric texture smooth satin cloth surface.

The color of smooth fabrics will have a lighter value or color compared with fabrics with a raised, brushed, napped or other irregular surface. Fabrics with an irregular surface absorb more of the white incident light than those with smoother surfaces, and so the former fabrics appear duller than the latter fabrics. The irregular surface fabrics have a lower value and chroma than the equivalent but smooth surfaced fabrics.

Cotton yarn dyed napped Jacqard fabric.

The optical properties of lusterous fabrics are the same as those given above for lusterous, translucent fibers and filament yarns. The color of a particular form of fabric will be affected by the surface of the fabric as well as by the optical properties of fibers and yarns from which they are produced.

Opaque and Translucent Fabrics

Opaque fabrics have a darker, duller color (i.e. less chroma and value) since these fabrics absorb most of the incident white light. Translucent fabrics have a lighter color than an equivalent opaque fabric. The color of a garment made from a translucent fabric will be influenced by the color and optical properties of the fabric as well as by the color of the skin against which the fabric is worn.

The Subjective Nature of Color Vision

Scientific instruments such as spectrophotometers (developed to measure color) have shown that each color is composed of specific wavelengths. The eye, however, is unable to view color consistently. This inability means that the color vision of human beings is subjective and so differences can be attributable to all or some of the following factors.

Tiredness of Eyes

This occurs when eyes are made to concentrate too long on one or a combination of colored objects. One of the following may result.

Positive After-Image

Prolonged exposure to a colored object may result in colors being seen for a few seconds after the object has been removed from view. This effect is called positive after-image. The effect is due to excessive stimulation of the photo-chemical substance within the retina. The excessive stimulation temporarily prevents the photo-chemical substance in the retina from regeneration, making the retina momentarily insensitive to light.

Successive Contrast

This occurs when, having concentrated upon a colored object, the eyes are turned away and see the complementary color(s) of the color(s) just viewed. Successive contrast is the most commonest type of after-vision. There is no simple explanation for this phenomenon.

Simultaneous Contrast

Sometimes an object being observed appears to be surrounded by a halo, or tinged with its complementary colors. This effect is called simultaneous contrast.

It is important to rest one's eyes regularly when making color comparisons to prevent any of the effects described above.

Emotional State of the Observer

The emotional state or past experiences involving colors can cause an observer to perceive colors differently.

Type of Illumination

Different sources of illumination will greatly influence the colors perceived by people.

Poor Illumination

Poor illumination provides inadequate light energy to stimulate the cones and so correctly perceive the actual color of the material being observed. With poor illumination, only the rods of the retina may be stimulated and colors observed will be restricted to shades of grey, black and faint green.

Direct Sunlight

Direct sunlight is characterized by a slightly yellow white light. That is because the colors yellow, orange and red represent over 40% of the sun's color spectrum - yielding the white color of sunlight a very slight yellow-red hue. Hence this source of light tends to impart a slight yellow tinge to all colors. The observer tends to ignore the slight yellow tinge of direct sunlight (which is picked up by a spectrophotometer) and so white paper appears white to the eye despite the yellow component of direct sunlight.

Indirect Sunlight

This is also referred to as south-light or north-light and is a blue-white light. South-light (i.e. a light reflected from the southern sky during daylight hours) contains an excess of blue light energy, because the molecules of the air scatter blue light waves more than the waves of the other colors.

This light tends to impart a slight blue tinge to all hues (as detected by a spectrophotometer). The observer tends to ignore the slight blueing effect of indirect sunlight.

Note: As a general rule blue-white is considered whiter white than yellow-white. Yellow-white materials give the impression of being somewhat soiled. The practice of "blueing" white laundry is still quite common, although this is more frequently and effectively carried out using optical brighteners, which are found in most domestic laundry detergents.

Incandescent Light

Incandescent light lacks the blue component of light. For example, most electric light bulbs emit incandescent light. This contains an excess of yellow and red light energy. Hence incandescent light is yellowish, although the eyes still perceive it as white light, until of course it is compared with fluorescent light.

Incandescent light therefore imparts a distinctly yellow-red appearance and has a similar effect on colors to direct sunlight.

Fluorescent Light

This light lacks yellow light waves. It contains an excess of blue and green light energy and a deficiency of red. Fluorescent light has a distinct blue color, although the eyes and brain will perceive it as a sterilized white light. The blueness of this light brightens any colors exposed to it.

Intensity of Illumination

The retina of the eyes needs time to adapt to varying levels of illumination. It takes time for the eye to adjust when one goes from a brightly lit area to one with little light and vice vera.

Contrast

Perception of colors can be influenced by the background against which the colored object is viewed. A yellow textile material when viewed against a grey background will result in the yellow hue having more value and chroma; that is, it will appear brighter than if it were viewed against a yellow background.

Age of the Observer

The natural ageing process of the hunman body will reduce one's ability to respond to various stimuli. Ageing yellows the lens of the eye and increases the yellow pigment in the central region of the retina. This results in older people seeing more yellow in colors, a fact which is not often accepted by older people.

Defective Color Vision

Approximately 8% of the male population and about 2% of the female population have defective color vision in one or more forms. Defective color vision can be described as the inability to see primary colors correctly and, in some instances, the inability to see color at all. The latter form of defective color vision results in the individuals being able to only see white, black and a range of greys. A person with this defect would sit in front of a color television set and would see a program in black and white only. Defective color vision is a sex-linked hereditary characteristic.

What number can you see in each of these discs?

Reference:

[1] E.P.G. Gohl and L.D. Vilensky, Textile Science, Longman Cheshire, Melbourne (1989).

No comments:

Post a Comment